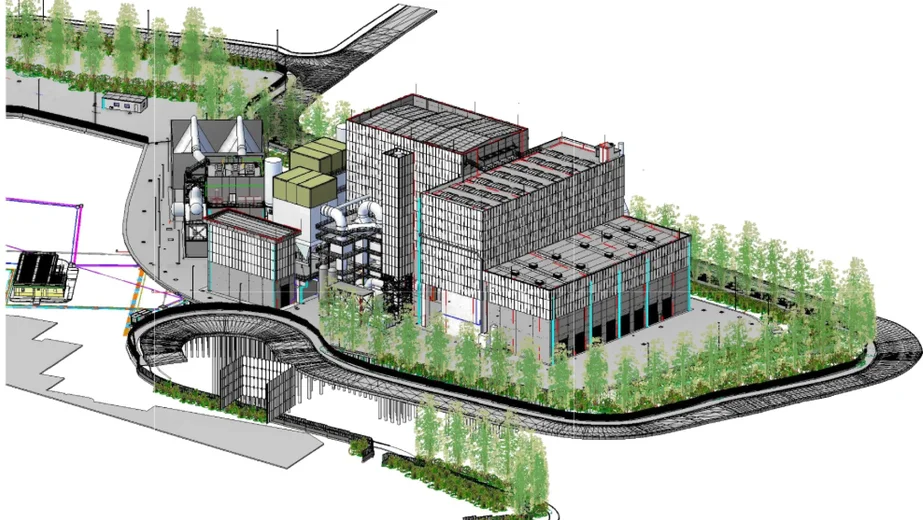

WtE Plant in Gorlice

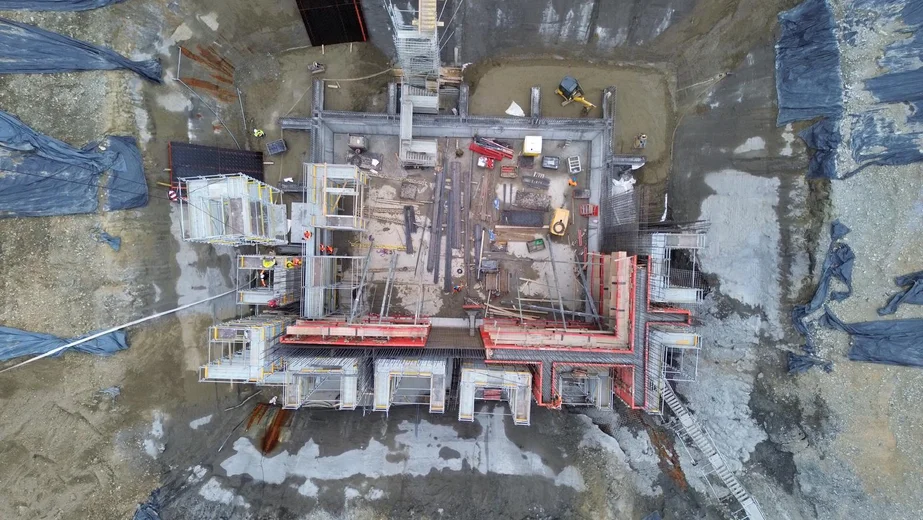

The construction of the WtE Plant in Gorlice is proceeding full speed ahead. The basements are ready and the plant is growing fast.

The investment is crucial for the region, as it will allow to solve the problem of waste management by processing non-recyclable waste, and in addition - in the process of cogeneration - system heat and electricity will be produced.

We are gratified to be involved in this process together with our partner PORR Polska, and we are pleased to share a recent photo of the implementation