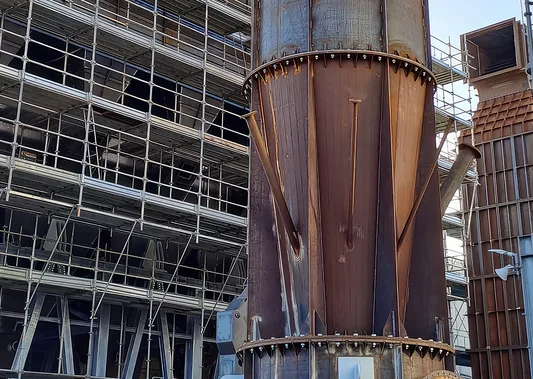

Sao Miguel

Portugalcategory

Waste to Energy + Combustion grates + FGTFuel mass flow

8.0 [t/h]In operation since

UCUnder

construction

The grate is designed to work with caloric values in the range from 6.0 to 15 MJ/kg. It provides the steam production of 24 t/h (20 MW).

More realizations from this category

Varese

Italy

Solvent Recovery Plant. Turn-Key Contract. The package has been positively commissioned allowing client to recover up to 98% of solvent and to comply with emission limits.

Read more

Hebei

China

Solvent Recovery Plant. Complete Engineering And Key-Components Supply. The package has been positively commissioned allowing client to recover up to 98% of solvent and to comply with emission limits.

Read more

Vigevano

Italy

Dmf Distillation Plant. Turn-Key Contract. Double effect plant to allow steam saving during distillation process. The package has been positively commissioned allowing client to recover up to 98% of DMF solvent.

Read more

Taranto

Italy

Vapour Recovery Unit. Skid Mounted Package.Skid mounted package to remove VOCs and H2S coming from bitumen storage tanks. The package has been positively commissioned allowing client to comply with local emission regulations.

Read more

Socar

Oman

Odour Abatement Package. Complete Engineering And Key-Components Supply.Odour abatement package to remove bad smelling odour coming from wastewater treatment of the refinery. The package has been positively commissioned allowing client to comply with local emission regulations.

Read more

Porto Torres

Italy

Regenerative Thermal Oxidizer - Pp And Pe Plants. Turn-key contract. Regenerative Thermal Oxidizer for treatment of waste gas containing chlorinated hydrocarbons coming from soil remediation of the ground of existing petrochemical complex.

Read more

Atessa

Italy

Waste Gas And Waste Liquid Thermal Oxidizer. Turn-Key Contract. Waste Gas and Waste Liquid thermal oxidizer with waste heat boiler and flue gas treatment to comply with local emission limits.

Read more

Dortmund

Germany

Thermal Oxidizer - Hydrogenated Resins Plant. The challenge was the supply of this thermal oxidizer with ATEX Zone 0 waste gas at inlet. Special hydrogenation gas burner has been supplied to reduce natural gas consumption.

Read more

Sumgayit

Azerbaijan

Regenerative Thermal Oxidizer - Pp And Pe Plants. Regenerative Thermal Oxidizer for treatment of waste gas during carbon black polyethylene production ATEX certified and wit dust filter to protect ceramic beds from potential clogging. The thermal oxidizer has been positively commissioned allowing client to comply with local emission regulations.

Read more

Santong

Malaysia

Acid Gas Oxidizer - Gas Processing Plant. Complete Engineering And Key-Components Supply. The thermal oxidizer has been positively commissioned allowing client to comply with local emission regulations and to replace existing acid gas incinerator that was non-compliant with emission limits.

Read more

Barga

Italy

Flue Gas Treatment. Turn-Key Contract. The challenge was the supply of this flue gas treatment during Ukraine’s war pandemic without any delay and within 10 months from the award.

Read more

Indiana

United States

Afterburner With Flue Gas Treatment. Complete Engineering And Key-Components Supply. The challenge was the supply of this flue gas treatment during COVID-19 pandemic without any delay and within 6 months from the award.

Read more

Massa

Italy

Flue Gas Desulfurization. Plant was erected and commissioned in 8 months from PO award ensuring compliance with emission limits especially for carbon monoxide and SOx, allowing client to earn benefits from steam production.

Read more

Wolverhampton

United Kingdom

Afterburner With Flue Gas Treatment. Turn-Key Contract. The challenge was the supply of this flue gas treatment during COVID-19 pandemic without any delay and within 9 months from the award.

Read more

Terni

Italy

Flue gas treatment WTE plant. Revamping of existing flue gas treatment plant to comply with new emission limits in according to BAT standards. SCR DeNOx with option for urea of ammonia solution injection.

Read more

Frankfurt – Fechenheim

Germany

The grate is designed to work with caloric values in the range from 8.0 to 16 MJ/kg. It provides the steam production of 50 t/h (44 MW).

Read more

Berlin - Neukölln line 1 and line 2

Germany

The grate is designed to work with caloric values in the range from 8.5 to 16 MJ/kg. It provides the steam production of 60 t/h (52 MW) for each one of the two lines.

Read more

Andernach

Germany

The grate is designed to work with caloric values in the range from 11 to 15 MJ/kg. It provides the steam production of 60 t/h (52 MW).

Read more

Kleannara Daehan line 1 and line 2

Korea

The grate is designed to work with caloric values in the range from 17 to 22 MJ/kg. It provides the steam production of 43 t/h (42 MW) for each one of the two lines.

Read more

Koentec Busan

Korea

The grate is designed to work with caloric values in the range from 17 to 23 MJ/kg. It provides the steam production of 41 t/h (36 MW).

Read more

Nijmegen 2

Netherlands

The grate is designed to work with caloric values in the range from 7.5 to 16 MJ/kg. It provides the steam production of 93 t/h (79 MW).

Read more

Asia Paper 1

Korea

The grate is designed to work with caloric values in the range from 20 to 27 MJ/kg. It provides the steam production of 30 t/h (27 MW).

Read more

Asia Paper 2

Korea

The grate is designed to work with caloric values in the range from 16.5 to 21 MJ/kg. It provides the steam production of 54 t/h (41 MW).

Read more

Bologna

Italy

Thanks to this WtE plant built by TM.E. every year 140 mln KWh of electricity is produced as a result of waste-to-energy, meeting the needs of 55,000 homes. 167,360,000 MJ is transferred to the district heating network, supplying power to 3,000 homes.

Read more

Valmadrera - Lecco

Italy

Silea, the project leader, has taken on metropolitan responsibility, ensuring that all municipalities in the region meet their environmental and waste management goals.

Read more

Terceira – Azores Islands

Portugal

The challenge was to build a plant on a small island in in the Azores archipelago, in the middle of the Atlantic Ocean, where logistical difficulties were particularly severe.

Read more

Bydgoszcz

Poland

One of the first Waste to Energy plants in Poland with the modern technology that allows achieving emission parameters significantly lower and more favorable for the environment than the acceptable standards.

Read more

Szczecin

Poland

The Waste to Energy plant was named EcoGenerator as it is a modern industrial plant, promoting the development of the waste management system in Szczecin and the region, improving the quality of life of residents.

Read more

Rzeszów

Poland

The plant ensures the energy security of Rzeszow by producing electricity and heat in the process of high-efficiency cogeneration. The produced energy and heat are used by residents and institutions in Rzeszow.

Read more

Beringen

Belgium

One of the biggest single WtE lines in Europe, generating energy by incinerating 200,000 tons of household waste, industrial waste and non-hazardous hospital waste.

Read more

Gdansk

Poland

This is a modern, environmentally responsible cogeneration plant with the biggest single WtE line in Poland designed to produce 109 GWh of electricity, with 509 TJ heat cogeneration.

Read morePerpignan

France

The plant treating 60.000 tones of Municipal Solid Waste per year is one of the most striking buildings in the region. TME’s scope of work was the supply of a new furnace and boiler system.

Read more

San vittore del lazio

Italy

The plant is characterized by high efficiency and reliability, which led the client to implement a fourth line, for which work is underway and TME has the honor of being confirmed again as Leader of the contractor Joint venture.

Read more